Composite Molding Sheet molding compound machine , SMC Sheet Molding Compounds Product,Fiberglass Compression Molding

Composition

Before the SMC can be used for moulding it must mature. This maturation time is necessary to allow the relatively low- viscosity resin to chemically thicken. The SMC will be kept in a maturation room at a controlled temperature (normally 48 hours at 30°C) and typically requires two to five days to reach the desired moulding viscosity. Usually SMC has a shelf life ranging from several weeks to several months from the date of manufacture. The time frame can be extended or reduced depending on the SMC formulation and storage conditions. A storage temperature of no higher than 20°C is recommended.

SMC can be formulated with a broad range of resin and reinforcement combinations to impart and enhance specific properties. For Class A surface requirements, for example, thermoplastic low profile additives are used to control the amount of shrinkage of the resin system during polymerisation. A general purpose formulation will have a shrinkage of around 0.2%, whereas a low-profile SMC will typically be as low as 0.05%, some are even zero shrinkage. Once cured SMC/BMC products show no post mould shrinkage what so ever. This is a particular benefit in the automotive industry, where low profile Class A SMC panels are often used alongside steel or aluminium in a hybrid design. Dimensional stability ensures precise panel fit and interface.

Due to its longer fibre length and higher fibre content, SMC has greater flexural strength and tensile strength than BMC. As a result the material tends to be used for larger flat parts with a more structural requirement combined with good cosmetics - such as vehicle body panels or building cladding panels. See Applications chapter for more details. Strength, rigidity and corrosion resistance are also essential attributes in other common SMC applications such as passenger car decklids, truck grilles, water storage tank panels and electricity meter cabinets.

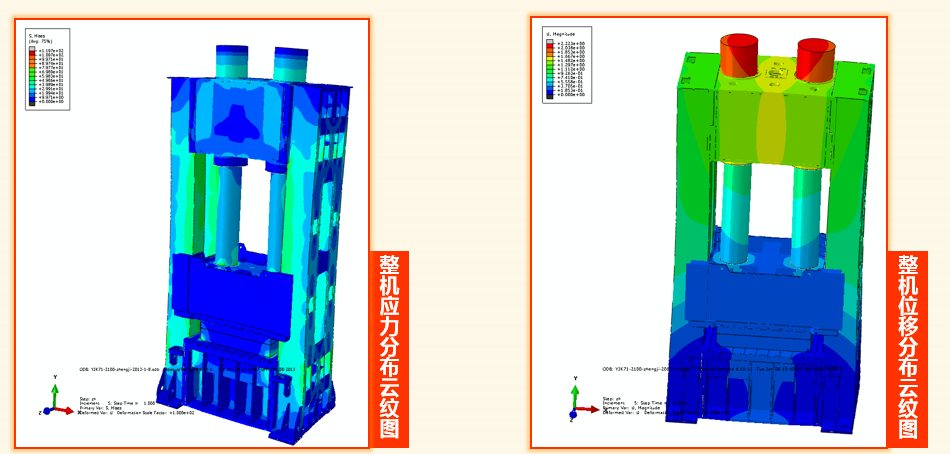

Company composite molding equipment performance characteristics

-

Nominal force: up to 5000 tons

-

Countertop: Maximum 5000mm

-

Slider stroke: up to 4500mm

-

The slider has a maximum fast return speed: 800mm/S

-

Slider minimum mold opening speed: 0.1mm/S

-

Pressure holding accuracy: 0.8MPa/hour per hour (no pressure compensation)

-

Touch screen plus PLC control system, bus control system

-

The four-corner leveling system meets the high-precision requirements for large-area thin-walled parts, and the leveling accuracy is ±0.05m.

-

The hydraulic system uses a piston accumulator, which is 40-60% lower than that of a conventional press.

-

Complete press mechanical locking safety system and electronic control interlock system.

Company composite molding equipment performance characteristics

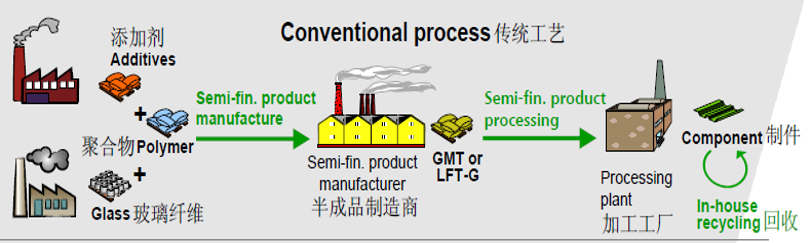

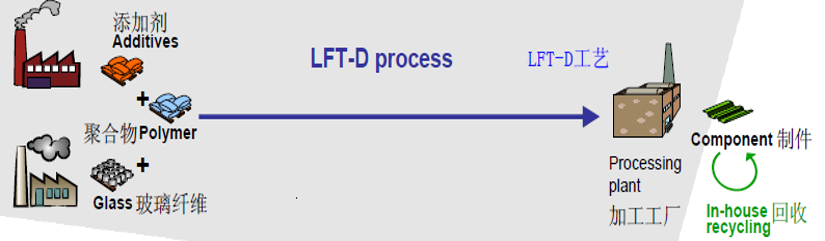

LFT-D long fiber reinforced thermoplastic directly inline molding

Main functional unit

1. Glass fiber yarn pretreatment unit: the fiber bundle is dispersed by the yarn dividing device, and the dispersed fiber bundle passes through the yarn guide frame and enters the yarn immersing device. After the immersion agent is infiltrated, it enters the drying device, and is dried and then wound on the package for preparation. Feed into the extruder.

Compounding and extruding unit: The base resin, auxiliary agent, fiber, etc. are mixed and plasticized in a first-order and second-order twin-screw extruder according to a set ratio by a raw material supply and feeding device, and the required size is extruded. band.

2. Insulation conveying unit: The LFT material strip extruded from the screw extruder enters the insulated double conveyor belt device and is to be grabbed by the robot.

Robotic gripping unit: The multi-joint robot is responsible for grabbing and placing the composite material block on the conveyor belt in the press cavity.

3. Press forming unit: After receiving the signal, the slider goes down and presses the block into the desired product.

4. Bus control unit: monitors all production units and their interactions and issues action commands to ensure accurate and safe operation. It consists of three networks: 1. PROFIBUS-DP bus; 2. ETHERNET (industrial Ethernet); SAFETY BUS (Safety Network).

-

The micro-opening technology of proportional servo is adopted, and the minimum height of stable mold opening can reach 0.1mm.

-

Adopting the unique fast and slow flexible switching technology, the slider fast and slow conversion realizes the no-flow breakpoint switching, and the safety of the slider operation is greatly improved.

-

The key parts are sealed by radial sealing, and the oil leakage of the press is effectively controlled.

-

The thermoplastic composite production line has a complete set of supply capabilities for material processing, molding processes, molds and automated full-line bus control integration.

Thermosetting resins form the matrix and chemical backbone of SMC/BMC, imparting the required blend of properties. Unsaturated polyester (UP) or vinyl ester (VE) are the resins most commonly used, and they undergo a cross-linking reaction when cured under heat and pressure. VE resins are used when there is a high technical requirement, for example where sustained heat and chemical resistance is needed. Good heat resistance is a characteristic of all thermosets and they differ from thermoplastics in that once the compound cures to a rigid solid, it will not soften at elevated temperatures or become brittle at lower temperatures. This means that SMC and BMC parts retain their original properties and dimensional accuracy over a broad range of temperatures.

Applications

Electrical & Electronics

(mechanical integrity and electrical insulation)

Low voltage and medium voltage energy systems Fuses and switchgear

Cabinets and junction boxes Motor and anchor insulations

Encapsulation of wiring and electronic circuits Electrical components with reduced surface resistivity Lamp housings

Mass Transportation

(light weight and fire resistance)

Train, tram interior and body parts Electrical components

Track switch components

Under the hood components for trucks

Automotive & Truck

(low fuel emissions through weight reduction)

Light weight body panels for vehicles

Lighting systems, headlamp reflectors and LED lighting Structural parts, front ends, interior dashboard parts body panels for trucks and agricultural vehicles

Building & Construction (durability and design freedom)

Drinking water tanks Panels

Doors

Building supply systems Drain and trench covers Access chambers